Phone: 0086-159-3381-6712

Phone: 0086-155-0324-9408

Tel/Fax: 0086-318-5227-301

E-mail: sales@wiremesh-chinafree.com

WhatsApp : 159-3381-6712

Address: Nanhuan Road, Anping County, Hengshui, Hebei, China. Post Code: 053600

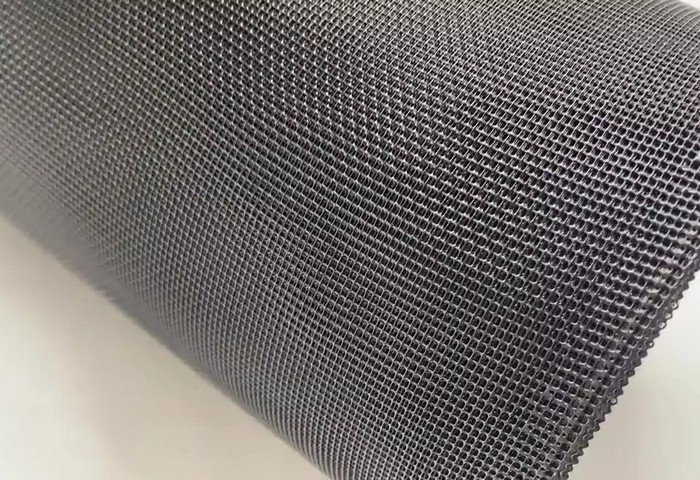

The mesh used in the roller thickening machine for thickening cellulose fibers is an important part of the machine. It is made of high quality stainless steel wire and woven into a mesh with a certain size and shape. The mesh is a kind of filter material with a large filter area and a large flow rate. It has the characteristics of high temperature resistance, corrosion resistance, wear resistance and good permeability. It is widely used in the thickening of cellulose fibers.

The mesh is made of stainless steel wire with a diameter of 0.2-0.5mm. The mesh size is 30-200 mesh, and the mesh size can be adjusted according to the needs of the thickening process. The mesh has a strong tensile strength, good toughness and long service life. It is an ideal filter material for the thickening of cellulose fibers.

In addition, the mesh has a smooth surface and no burr, which can reduce the damage to the cellulose fibers during the thickening process and improve the quality of the thickening.

In summary, the mesh used in the roller thickening machine is an important part of the machine. It is made of high quality stainless steel wire and is woven into a mesh with a certain size and shape. It has the characteristics of high temperature resistance, corrosion resistance, wear resistance and good permeability. It is an ideal filter material for the thickening of cellulose fibers.