Sintering Furnace Mesh Belt Characteristics & Maintenance

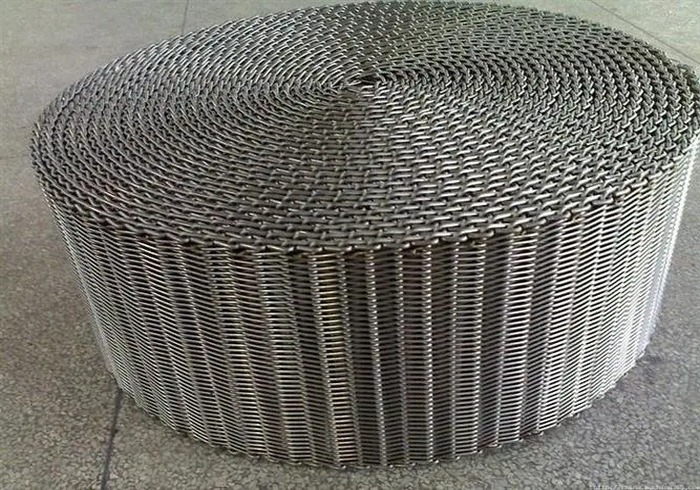

Sintering furnace mesh belt is a kind of conveyor belt used for conveying and heating sintering material, which is widely used in steel, aluminum and other industrial fields. It is composed of multiple layers of wire mesh and steel belts of different materials, which can operate stably in high temperature and high pressure environments. The sintering furnace mesh belt mainly includes multiple parts such as feeding section, heating section, cooling section and discharging section. It can automatically control parameters such as temperature, speed and tension, so that the sintering material can be heated evenly and reach the required desired sintering effect.

Sintering furnace mesh belt is a kind of conveyor belt for sintering furnace, which has the following characteristics:

1. Strong high temperature resistance, capable of withstanding high temperature operation and thermal stress.

2. Strong wear resistance, can withstand high-strength tension and friction.

3. Strong corrosion resistance, able to resist the erosion of various chemical substances.

4. Reasonable structure design ensures smooth operation and long-term use effect.

5. Easy to install and maintain, easy to clean and maintain.

Use and maintenance items:

1. During use, care should be taken to clean the sundries and dirt on the surface of the conveyor belt in time to prevent damage to the conveyor belt.

2. After the equipment is shut down, the debris on the upper and lower surfaces of the conveyor belt should be cleaned up in time and kept dry.

3. Regularly check the condition of lubricating oil and hydraulic oil, and replace or replenish lubricant in time.

4. Pay attention to the tension of the mesh belt of the sintering furnace to avoid breakage of the conveyor belt caused by looseness or overtightness.