GH4169 Alloy Wire Mesh Characteristics, Technical Standards

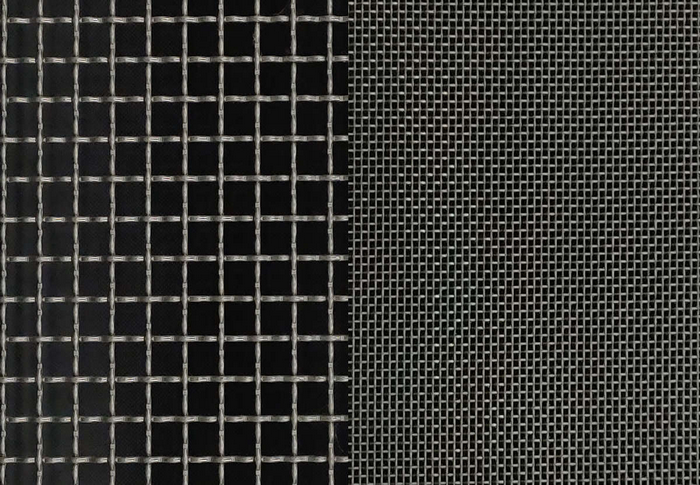

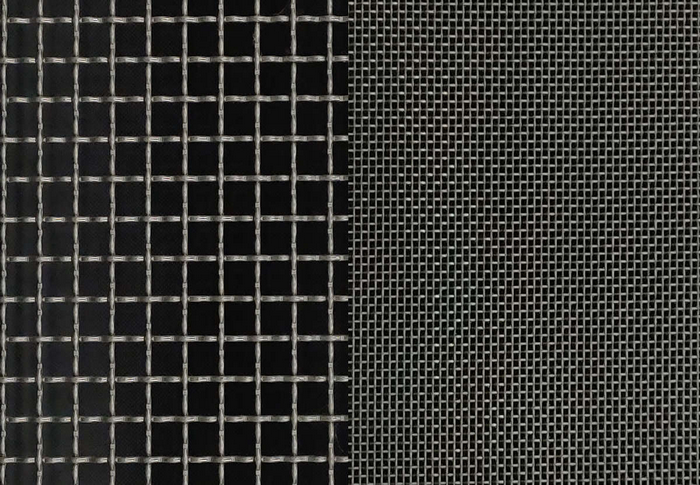

GH4169 high temperature alloy wire mesh is famous as GH4169 high temperature alloy wire woven mesh, GH4169 high temperature alloy wire filter, GH4169 high temperature alloy wire screen, and GH4169 high temperature alloy wire square hole mesh.

The GH4169 alloy has good comprehensive properties in the temperature range of -253 to 700 ° C, and the yield strength below 650 ° C ranks first among deformed superalloys, and has good fatigue resistance, radiation resistance, oxidation resistance, corrosion resistance, and good Good processability and welding performance. It can manufacture various parts with complex shapes, and has been widely used in the above temperature range in aerospace, nuclear energy, petroleum industry and extrusion dies.

Another characteristic of GH4169 superalloy wire mesh is that the alloy structure is particularly sensitive to the thermal processing process. Mastering the phase precipitation and dissolution laws in the alloy and the relationship between structure, process and performance can formulate reasonable and feasible process regulations for different use requirements. , you can get a variety of parts that can meet different strength levels and use requirements. The varieties supplied include forgings, forged bars, rolled bars, cold-rolled bars, round cakes, rings, plates, strips, wires, tubes, etc. It can be made into discs, rings, blades, shafts, fasteners and elastic elements, plate structural parts, casings and other parts for long-term use in aviation.

1GH4169 material grade

GH4169 (GH169)

Similar grades to 2GH4169

Inconel718 (USA), NC19FeNb (France)

3GH4169 technical standards for materials

GJB 2612-1996 "Specification for Welding Superalloy Cold-drawn Wire Material"

HB 6702-1993 "GH4169 Alloy Bars for WZ8 Series"

Q/6S 1034-1992 "GH4169 Alloy Bars for High Temperature Fasteners"

Q/3B 548-1996 "GH4169 Alloy Forgings"

Q/3B 548-1996 "GH4169 Alloy Forgings"

Q/3B 4048-1993 "YZGH4169 Alloy Bars"

Q/3B 4050-1993 "GH4169 Alloy Sheet"

Q/3B 4051-1993 "GH4169 Alloy Wire"

GB/T14992-2005 "High Temperature Alloys"

The chemical composition of GH4169 superalloy wire mesh is divided into 3 categories: standard composition, high-quality composition, and high-purity composition. Table 1-1. On the basis of standard components, the high-quality components reduce carbon and increase niobium, thereby reducing the number of niobium carbides, reducing fatigue sources and strengthening phases, increasing the content of anti-fatigue, and improving the purity and comprehensive performance of materials.

For the GH4169 alloy used in nuclear energy, the content of boron needs to be controlled (the composition of other elements remains unchanged), and the specific content should be determined through negotiation between the two parties in the process. When ω (B) ≤ 0.002%, in order to distinguish it from the GH4169 alloy used in the aerospace industry, the alloy grade is GH4169A.