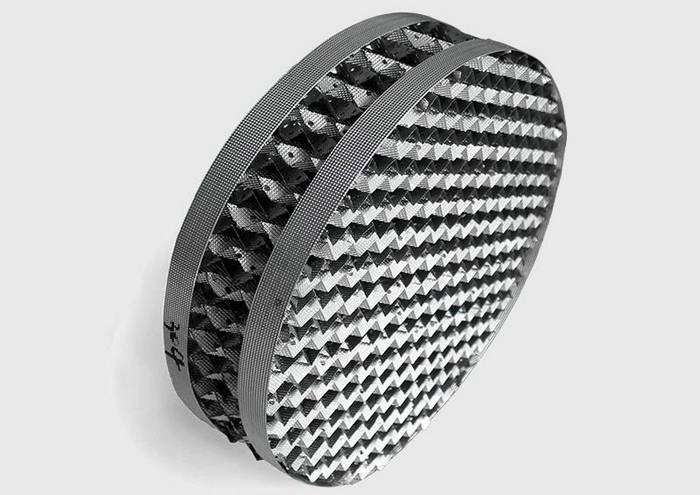

Structured Packing Offers High Separation Efficiency for Packed Tower

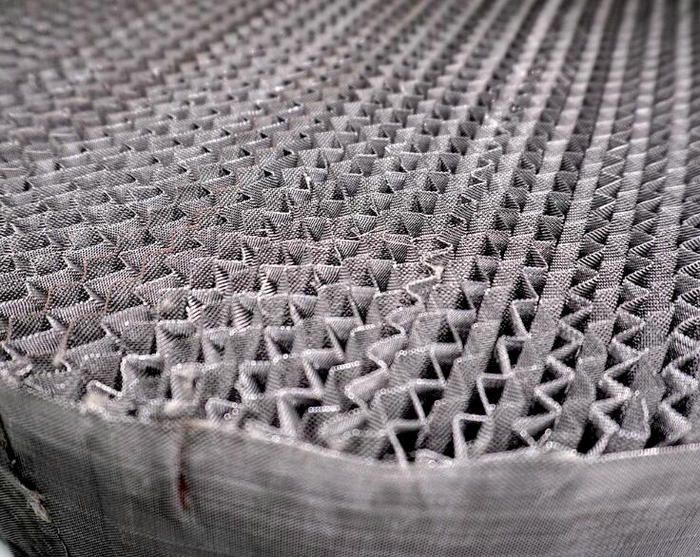

Structured packings in metallic, plastic and ceramic materials, are made into different geometrical shapes and corrugation angles for different types and sizes packed towers. Multi-types, easy assemble, high efficiency and low maintenance make them widely used in fine chemicals, solvent recovery, chemical product refining, atmospheric rectification and vacuum rectification.

Material

Stainless steel, copper, PP, PVC, PVDF, CPVC, ceramic, etc.

Feature

Metallic/plastic/ceramic materials to suit different environments.

Large contacting surface area and uniform liquid and gas distribution.

Reduced liquid hold-up and high flux.

Ideal for distillation, separation, purification and other processes.

High temperature and chemical stability for high performance.

There are five main kinds of structured packing, including wire gauze, perforated corrugated, expanded corrugated, protruded corrugated and ceramic structured packings. Here is the PDF including structure, common specs and applications of different structured packing. Just browse and refer to them and choose the best for you.

Application

The classic application fields for structured metal packing are processes with following operation conditions:

Low liquid loads.

High gas loads.

Requirement for low pressure drop.