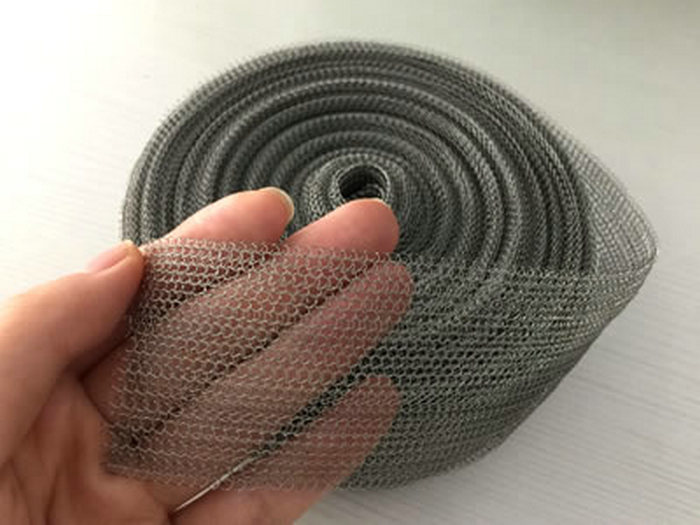

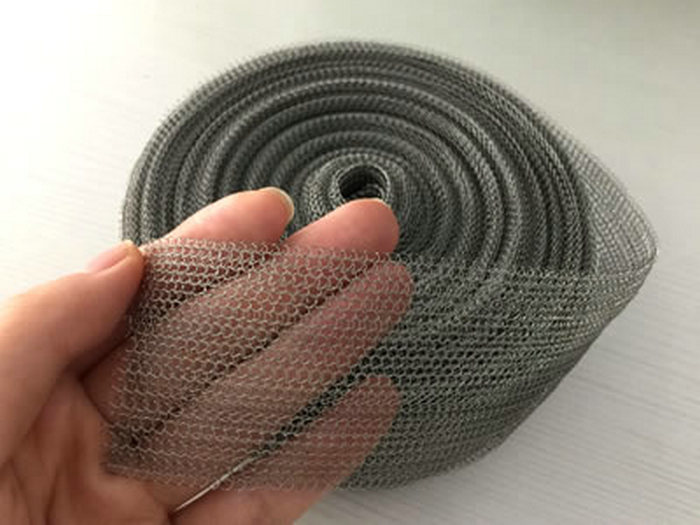

Knitted wire mesh products are applied to those applications including cryogenic, high temperature, corrosive atmosphere, heat conductive, high usage, or special service applications.

Our knitted wire mesh is made from all material available in wire shapes for processing of the following parts:

Filters Oil and Air Breather Elements

Catalytic Converter Mesh Insulator Blanket Mesh

Mufflers and Silencers

Copper Mesh Oil-Bath Separators

Mist Elimination Pads Ground Wire Mesh

Main Materials Applied for Knitted Mesh:

Monel knitted wire mesh has good corrosion resistance in all extreme environments and it is reasonably conductive and is tough with high tensile strength, giving good wear characteristics.

Knitted wire mesh made of tinned copper clad steel has the best shielding performance of all wires used in knitted meshes, combining low contact resistance with a small degree of permeability. It is not suitable for highly abrasive applications where the TIN plating may wear away to expose the copper. The corrosion resistance of tinned copper clad steel knitted wire mesh is suitable for most applications.

Aluminum knitted wire mesh is mechanically weak and will readily take a compression set and this combined with its readiness to form a non-conducting oxide.

Stainless steel knitted mesh is often used as a protective final layer over the other knitted mesh gasket, materials on order to provide a wear-resistant contact surface.

Application

Liquid or gas filtration materials.

Engine breathers in vehicles.

Shielding mesh in electronic field.