Phone: 0086-159-3381-6712

Phone: 0086-155-0324-9408

Tel/Fax: 0086-318-5227-301

E-mail: sales@wiremesh-chinafree.com

WhatsApp : 159-3381-6712

Address: Nanhuan Road, Anping County, Hengshui, Hebei, China. Post Code: 053600

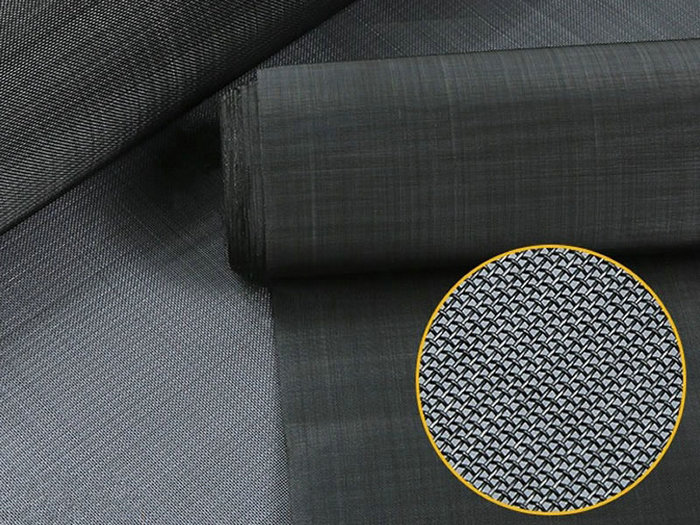

Woven black wire cloth, also known as Black wire cloth or Black wire mesh, is a versatile filtration and structural material made from high-quality annealed low-carbon steel wire. Its name, though misleading, refers to its woven construction rather than fabric. This material is distinguished by its uniform mesh structure, durability, and adaptability across various industries.

Key Features

Conclusion

Woven black wire cloth is an indispensable material for precision filtration and structural reinforcement. Its adaptability to diverse weave patterns and robust performance makes it a cost-effective solution across multiple sectors.