Alloy L605 Wire Mesh Serve in Artificial Heart Valve

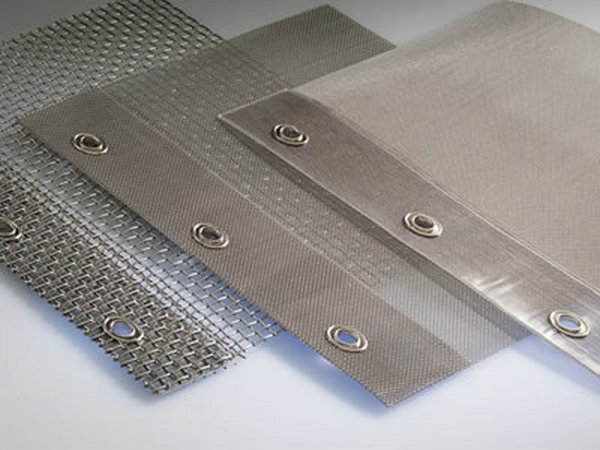

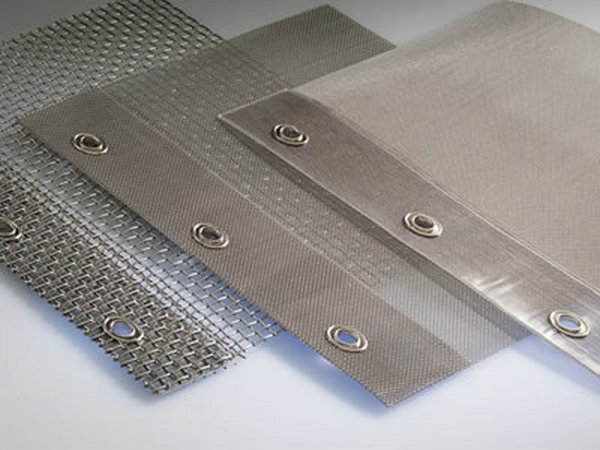

Alloy L605 wire mesh belongs to cobalt-nickel-chromium-tungsten alloy, which possesses excellent high temperature and oxidation resistance.

Alloy L605 wire mesh also called haynes 25 wire mesh can be made into filter disc, heating element or be widely used in gas turbine engine components, artificial heart valve, metal materials filter equipment.

Specifications of alloy L605 wire mesh:

Weaving methods: plain weave, twill weave, dutch weave.

Packing:

Wrapped with waterproof paper, plastic film; In carton, wooden boxes or pallets.

Alloy L605 Wire Mesh Chemical Composition (%) Co-50.143% Cr-20.01% W-14.96% Ni-10.02% Mo-2.750% Mn-1.49% Si-0.550% P-0.017% C-0.014% S-0.001%.

Specifications of Alloy L605 wire mesh

| Mesh |

Wire Diameter |

Opening (mm) |

| SWG |

mm |

inch |

| 2 mesh |

15 |

1.800 |

0.07 |

10.90 |

| 3 mesh |

16 |

1.600 |

0.063 |

6.866 |

| 4 mesh |

18 |

1.200 |

0.047 |

5.150 |

| 5 mesh |

20 |

0.910 |

0.036 |

4.170 |

| 6 mesh |

22 |

0.711 |

0.028 |

3.522 |

| 8 mesh |

23 |

0.610 |

0.024 |

2.565 |

| 10 mesh |

25 |

0.508 |

0.020 |

2.032 |

| 12 mesh |

26 |

0.457 |

0.018 |

1.660 |

| 14 mesh |

27 |

0.417 |

0.016 |

1.397 |

| 16 mesh |

29 |

0.345 |

0.014 |

1.243 |

| 18 mesh |

30 |

0.315 |

0.012 |

1.096 |

| 20 mesh |

30 |

0.315 |

0.0124 |

0.955 |

| 22 mesh |

30 |

0.315 |

0.0124 |

0.840 |

| 24 mesh |

30 |

0.315 |

0.0124 |

0.743 |

| 26 mesh |

31 |

0.295 |

0.0116 |

0.682 |

| 28 mesh |

31 |

0.295 |

0.0116 |

0.612 |

| 30 mesh |

32 |

0.274 |

0.011 |

0.0573 |

| 32 mesh |

33 |

0.254 |

0.010 |

0.540 |

| 34 mesh |

34 |

0.234 |

0.0092 |

0.513 |

| 36 mesh |

34 |

0.234 |

0.0092 |

0.472 |

| 38 mesh |

35 |

0.213 |

0.0084 |

0.455 |

| 40 mesh |

36 |

0.193 |

0.0076 |

0.442 |

| 42 mesh |

36 |

0.193 |

0.0076 |

0.412 |

| 44 mesh |

37 |

0.173 |

0.0068 |

0.404 |

| 46 mesh |

37 |

0.173 |

0.0068 |

0.379 |

| 50 mesh |

37 |

0.173 |

0.0068 |

0.335 |

| 60 × 50 mesh |

36 |

0.193 |

0.0076 |

- |

| 60 × 50 mesh |

37 |

0.173 |

0.0068 |

- |

| 60 mesh |

37 |

0.173 |

0.0068 |

0.250 |

| 70 mesh |

30 |

0.132 |

0.0052 |

0.231 |

| 80 mesh |

40 |

0.122 |

0.0048 |

0.196 |

| 90 mesh |

41 |

0.112 |

0.0044 |

0.170 |

| 100 mesh |

42 |

0.012 |

0.004 |

0.152 |

| 120 mesh |

44 |

0.081 |

0.0032 |

0.131 |

| 140 mesh |

46 |

0.061 |

0.0024 |

0.120 |

| 160 mesh |

46 |

0.061 |

0.0024 |

0.098 |

| 180 mesh |

47 |

0.051 |

0.002 |

0.090 |

| 200 mesh |

47 |

0.051 |

0.002 |

0.076 |

| 220 mesh |

48 |

0.051 |

0.002 |

0.065 |

| 250 mesh |

48 |

0.041 |

0.0016 |

0.0061 |

| 280 mesh |

48 |

0.0035 |

0.0014 |

0.0056 |

| 300 mesh |

49 |

0.031 |

0.0012 |

0.054 |

| 320 mesh |

49 |

0.031 |

0.0012 |

0.046 |

| 350 mesh |

49 |

0.031 |

0.0012 |

0.039 |

| 400 mesh |

50 |

0.025 |

0.00098 |

0.0385 |

Alloy L605 wire mesh features:

Excellent resistance to high temperature and oxidation;

Resist to seawater environment and acidic fluids;

Good corrosion and abrasion resistance;

Good welding performance and strength.

Alloy L605 wire mesh applications:

Filter or heating element;

Element of gas turbine, artificial heart valve, or in aerospace, high temperature equipment.