Paper Pulp Molding Mesh: The Eco-Friendly Packaging Revolution

What is Paper Pulp Molding Mesh?

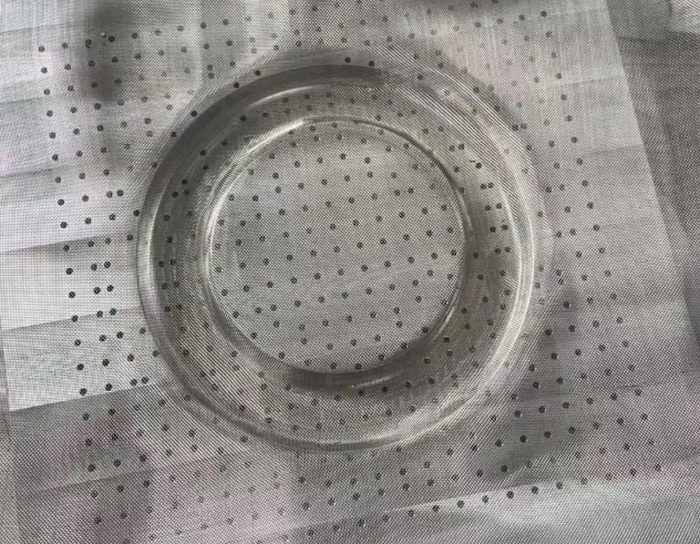

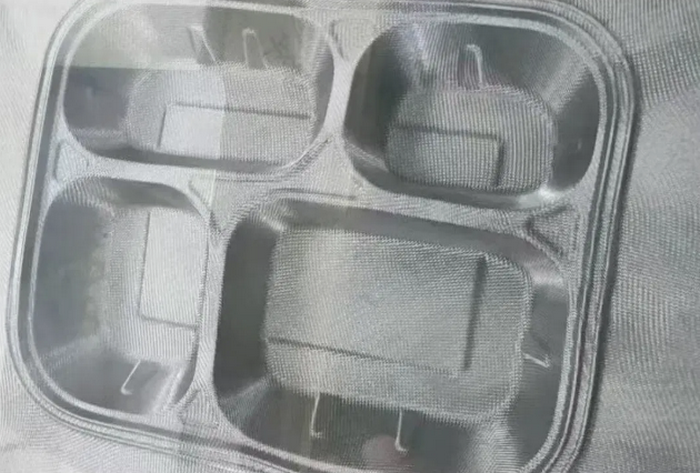

Paper pulp molding mesh is a specialized filtration material used in the production of molded pulp packaging. As the backbone of sustainable packaging manufacturing, this precision-engineered mesh:

Transforms recycled paper slurry into precise 3D shapes

Achieves consistent thickness and drainage efficiency

Comes in various weave patterns (single-layer, multi-layer, composite)

Key Benefits of Our Pulp Molding Mesh

1. Superior Durability

Withstands 100,000+ molding cycles while maintaining dimensional stability, reducing replacement frequency by 40% compared to industry standards.

2. Optimized Drainage Performance

Our patented hexagonal weave pattern accelerates water drainage by 30%, significantly improving production efficiency.

3. Customization Options

Available in:

Mesh counts: 60-200mesh, twill weave (40 mesh)

Specifications: 400×600mm, 600×800mm, 500×700mm, 550×750mm , etc.

Materials: 304/316 stainless steel

Shapes: Custom contours for egg trays, fruit packaging, electronics cushioning.

Applications Across Industries

Food Packaging: Egg trays, fruit containers (FDA compliant)

Electronics: Shock-absorbing inserts for smartphones

Medical: Sterilizable packaging for surgical instruments

E-commerce: Protective packaging for fragile items

Why Choose Our Pulp Molding Mesh?

15+ Years of industry expertise

ISO 9001 certified manufacturing

24/7 Technical Support

Global Shipping with 30-day delivery guarantee

FAQs

Q: How often should molding mesh be replaced?

A: Typically every 50,000-150,000 cycles depending on material grade and maintenance.

Q: Can you create custom mesh patterns?

A: Yes, we provide CAD-based custom weaving within 2-3 week lead time.

Q: What's the MOQ?

A: Standard products 10㎡, custom orders 50㎡ minimum.