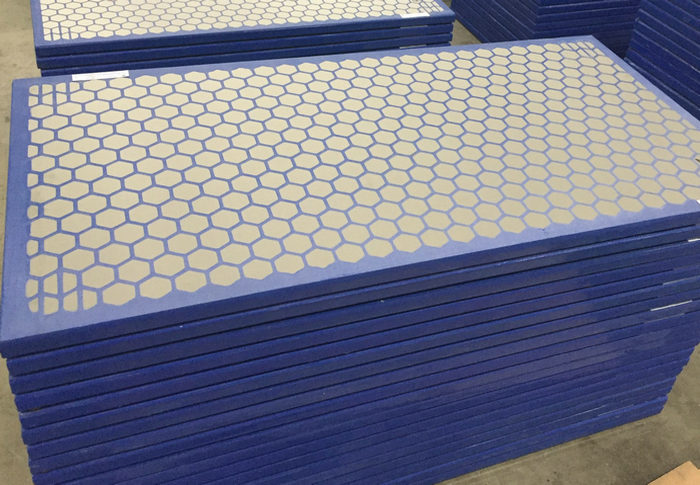

Shale Shaker Screens for Oil Fields and Coal Projects

Choosing the right wire cloth for shale shaker screens is important to ensure optimal performance and longevity of the screens. Here are some factors to consider when selecting wire cloth for shale shaker screens:

Mesh size: The mesh size of the wire cloth should be selected based on the particle size of the material being processed. A finer mesh size is suitable for smaller particles, while a coarser mesh size is better for larger particles.

Wire diameter: The wire diameter should be chosen based on the strength and durability required for the application. Thicker wires are stronger and more durable, but may reduce the screening efficiency.

Weave type: The weave type of the wire cloth can affect the screening efficiency and the ability to handle different types of materials. Common weave types include plain weave, twill weave, and Dutch weave.

Material: The material of the wire cloth should be selected based on the chemical and physical properties of the material being processed. Common materials include stainless steel, carbon steel, and polyurethane.

Screen tension: The tension of the wire cloth on the screen should be adjusted to ensure proper screening and prevent premature wear.