PVC coated steel wire can be used in daily life binding and industrial tying as tying wire. PVC coated wire also can be used in wire hanger or handicraft production.

PVC coated wire is material with an additional layer of polyvinyl chloride or polyethylene on the surface of the annealed wire, galvanized wire and other materials. The coating layer is firmly and uniformly attached to the metal wire to form the features of anti-aging, anti-corrosion, anti-cracking, long life and other characteristics.

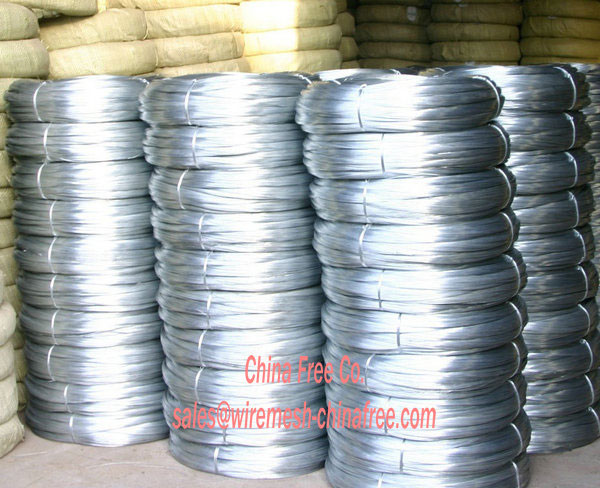

Materials before PVC coating: steel wire, galvanized wire, redrawing wire, annealed wire, etc.

Surface: plastic covering or plastic coating.

Color: green, blue, gray, white and black; other colors also available on request.

Average tensile strength: 350 N/mm2 – 900 N/mm2.

Elongation: 8% - 15%.

Wire diameter before coating: 0.6 mm – 4.0 mm (8–23 gauge).

Wire diameter with coating: 0.9 mm – 5.0 mm (7–20 gauge).

Plastic layer: 0.4 mm – 1.5 mm.

Wire diameter tolerance: ±0.05 mm.

PVC coated wire application:

Wire hanger or handicraft production.

Tie wire for daily life binding or industrial tying.

Protective chain link fences.

Construction of industrial security fences.

Freeways and tennis courts.