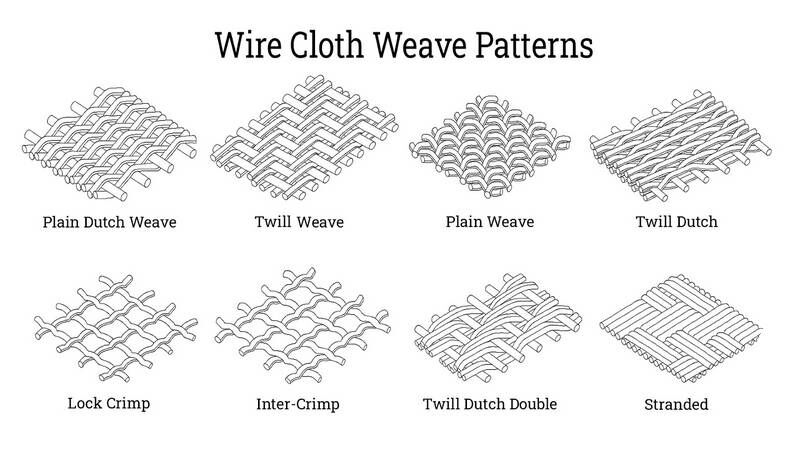

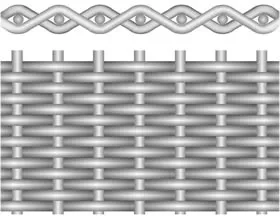

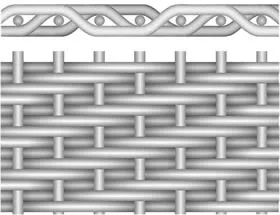

Dutch weave wire cloth is different from plain weave wire cloth and twill woven wire cloth, the dutch weave wire cloth has different diameter in the weft and warp directions.

Commonly the warp wire is coarser wire, which can supply the high tensile strength for the wire mesh. The weft wire is finer wire, which can ensure the excellent filtering performance.

This unique structure with greater strength and finer openings is primarily used as a filter cloth.

Plain dutch weave wire cloth is the combination of dutch weave and plain weave. It has two sizes of wire diameters like the dutch weave. Each warp wire with coarse wire diameter passes alternately over and under one weft wire to supply high tensile strength for the netting.

The weft wire with fine wire diameter alternately passes over and under one warp wire to form a fine opening for filtering.

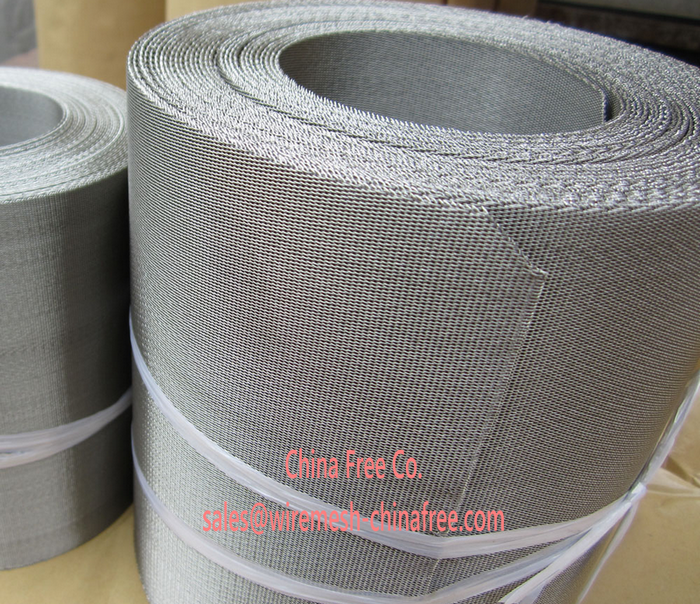

The plain dutch weave woven wire cloth is mainly used for filtering and separating liquid and slurry products.

Specification:

| Mesh per Inch (Warp X Weft) | Wire Diameter (Warp X Weft) |

| 12mesh x 64mesh | 0.58mm x 0.40mm |

| 14mesh x 88mesh | 0.50mm x 0.33mm |

| 24mesh x 110mesh | 0.355mm x 0.25mm |

| 30mesh x 150mesh | 0.23mm x 0.18mm |

| 40mesh x 200mesh | 0.18mm x 0.14mm |

| 50mesh x 250mesh | 0.14mm x 0.11mm |

| 60mesh x 300mesh | 0.14mm x 0.09mm |

| 70mesh x 400mesh | 0.12mm x 0.08mm |

Advantages of the plain dutch weave wire cloth:

Greater mechanical stability.

Finer opening for better filtration efficiency and quality.

Coarser wire for higher tensile strength.

Twill dutch woven wire cloth is the combination of dutch weave and twill weave. The weft wires passes alternately over and under two warp wire forming a finer mesh in the warp direction and the warp wires forms a coarser mesh in the warp direction in the same weaving.

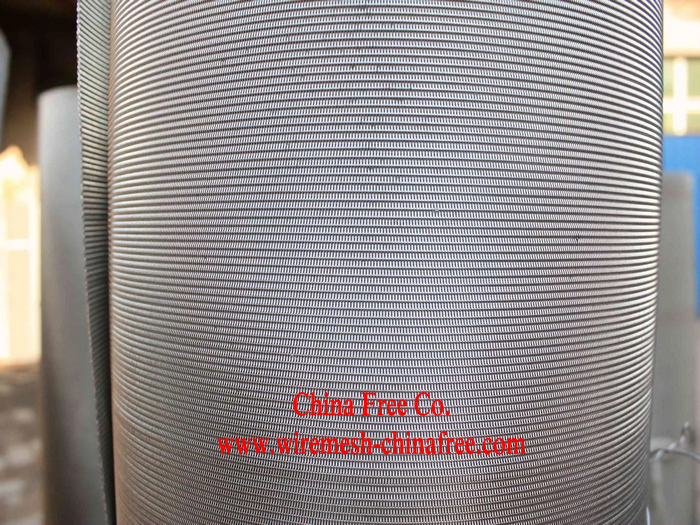

Twill dutch woven wire mesh is superior to the twill woven wire cloth because of the finer openings. It can support greater loads than the dutch weave wire mesh. It is used for filtering heavy materials.

specification:

| Mesh per Inch (Warp X Weft) | Wire Diameter (Warp X Weft) |

| 24mesh x 220mesh | 0.30mm x 0.25mm |

| 20mesh x 250mesh | 0.30mm x 0.20mm |

| 50mesh x 500mesh | 0.14mm x 0.11mm |

| 80mesh x 700mesh | 0.10mm x 0.08mm |

| 165mesh x 800mesh | 0.071mm x 0.045mm |

| 200mesh x 600mesh | 0.071mm x 0.050mm |

| 200mesh x 1400mesh | 0.14mm x 0.09mm |

| 165mesh x 1400mesh | 0.071mm x 0.04mm |

| 325mesh x 2300mesh | 0.035mm x 0.025mm |

| 400mesh x 2800mesh | 0.030mm x 0.02mm |

Advantages of the twill Dutch weave wire mesh:

Better filtering performance.

Higher tensile strength.

Can be used for filtering ultra-fine products.

Much more stable structure.